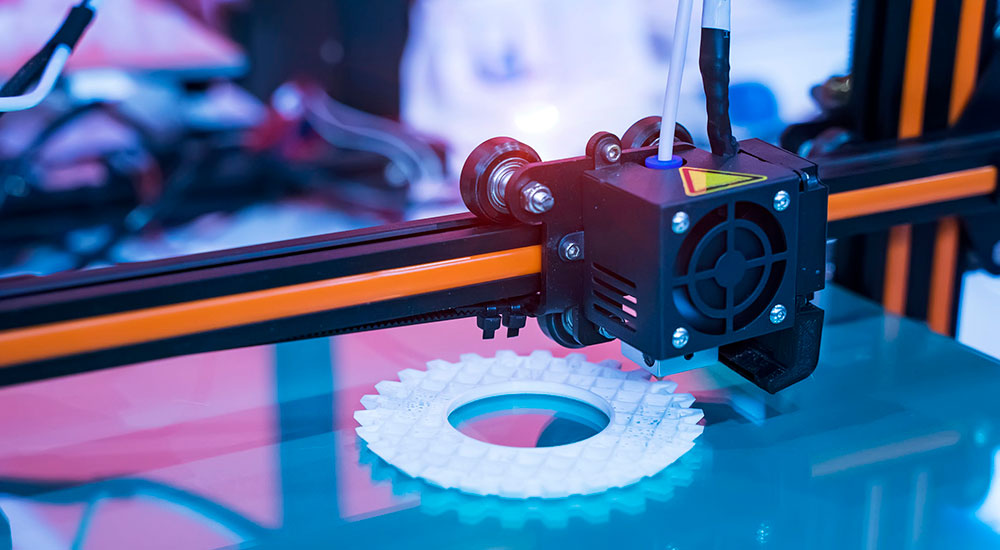

3D modeling: become part Italian excellence

When we talk about 3D modeling, we are referring to a rather broad sector that can overlook so many manufacturing and design industries.

It is an increasingly growing sector in our country and represents one of the excellences of Made in Italy.

How to become a Technologist for the Manufacturing and Design industry?

Jobsacademy together with as many as 68 Partner companies has created a course that will allow you to enter the world of work with the experience and skills needed to make a difference.

The 3D Modeling course is a two-year course, which includes 870 hours of technical and professional training covering all what are called “hard skills”, 300 transversal hours, the so-called “soft skills”, and finally 800 hours of internships in companies that will allow you to put into practice the notions learned in the classroom.

The strength of the course, like JAC’s other courses, is definitely the close ties like the companies in the sector: In the classroom, the professors are experts in the field who work firsthand in the company every day and are therefore familiar with the needs and changes in the sector.

What will you be able to do upon completion of the course?

- Develop products and process improvements

- Develop technical drawings using appropriate software

- Define product data sheets

- Perform technical operations in the materials testing laboratory

- Conduct research activities

- Conceptualizing industrial product design

Where might a senior technician in 3D modeling go to work?

Sectors where you will be able to work include mechanical or mechatronics companies, professional firms that collaborate with companies that make products, production departments, public and private testing laboratories, research centers, and universities. These are also joined by companies in the chemical and mechanical industry or pharmaceutical agencies.

Become a CAD-CAM Designer.

CAD designers use technology to generate designs for complex projects. These designs can be used to create 2D images, a process known as surface modeling, 3D images, or solid modeling.

Using computer-generated plans, CAD designers must work with other team members and departments to set deadlines, budgets, and actively collaborate with management and production in making decisions about the materials that will be used to complete the project.

Responsibilities:

- Use specific software to create detailed 2D or 3D designs for complex projects.

- Collaborate with other departments to establish deadlines and budgets.

- Knowledge of materials engineering and their different types.

- Ability to analyze data and situations and find creative solutions.

- Keep abreast of industry and engineering standards.

Become a product design manager.

The Product Design Manager is responsible for coordinating and supervising the development of new products, improving existing products, or optimizing their design.

Responsibilities:

- Provide guidance to product design teams

- Supervise the team on a daily basis in product design and development activities.

- Work with the team to prepare product design specifications

- Provide design solutions to meet cost-effectiveness and on-time delivery.

- Implement process improvements

- Identify resource requirements and execute workload assignments to meet product design goals.

- Analyze and resolve product problems in a timely manner.

Become a research laboratory technician

The laboratory and research technician is the person in the company who sets up, operates, and ensures the functionality of laboratory equipment. He or she is also the one who tests, monitors and keeps detailed records of experiments.

More experienced technicians maintain complex computer equipment, interpret data, develop conclusions, and devise solutions to more or less complex problems.

Responsibilities:

- implement research projects

- test different hypotheses of operations

- evaluate data

- perform general laboratory tasks

- write and submit reports

Become a CNC Machine Technician Super.

This type of technician is the operator assigned to run CNC machine tools, which are those machines used for automated production.

Responsibilities:

- Produces machined parts by programming, setting up and operating a computer numerical control (CNC) machine;

- Maintains high standards of quality and safety;

- Keeps records;

- Maintains equipment and supplies.

Become a Quality Control and Maintenance Officer

The quality control and maintenance officer is the one who proceeds to do product testing during the various stages of processing, as well as process monitoring and product verification.

Responsibilities:

- Inspection of output samples

- Verifying that the assembly or production line adheres to standards

- Recording inspection results by compiling reports

- Monitoring the use of equipment

- Maintain functioning measuring equipment

If you are curious about joining this industry: Sign up for the course