What are the outgoing professional figures of the Mechanics and Automation 4.0 pathway

After completing the mechatronics course, there are many interesting career opportunities available to you. Here are some of the most common positions that you can aspire to:

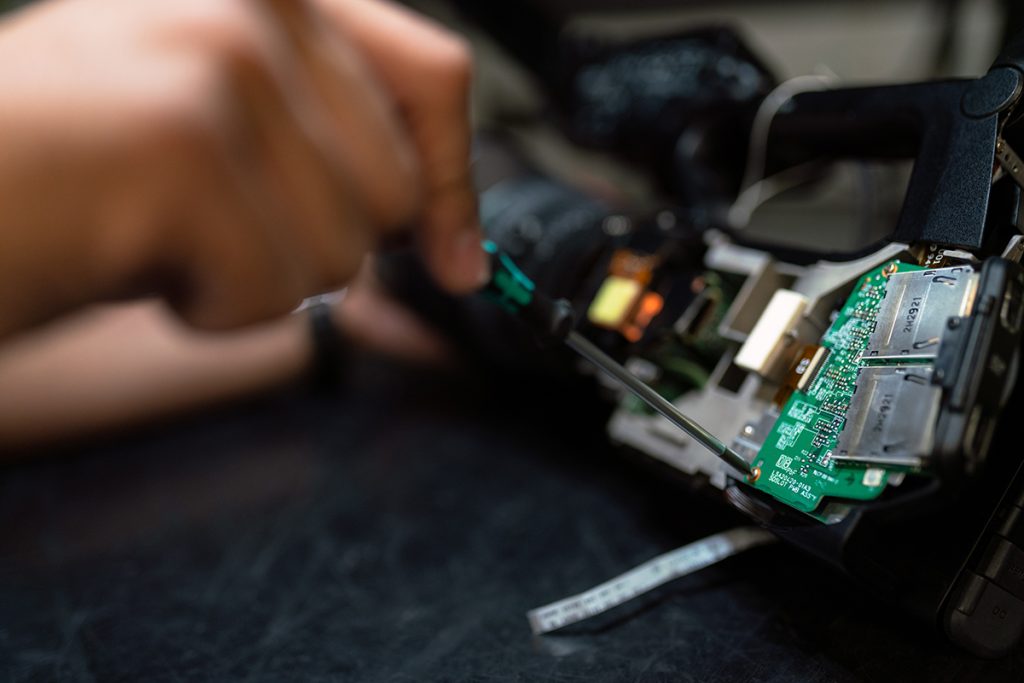

INSTALLATION AND MAINTENANCE TECHNICIAN FOR AUTOMATIC SYSTEMS

As an automatic systems installer and maintenance technician, you will be responsible for installing and maintaining automation equipment, machines, plants and systems. This includes connecting electrical, electromechanical, electronic, pneumatic or hydraulic equipment, as well as preventing and troubleshooting any problems to ensure the proper functioning of automation systems. You could work in industrial and service companies with automation systems, as well as in small/medium-sized companies or craft enterprises providing specialised maintenance services.

AUTOMATIC SYSTEMS PROGRAMMER TECHNICIAN

As an automatic systems programmer technician, you will be responsible for designing and programming the control logic and management of electronic components of automation systems. You may work in the technical department or at customer sites for the design, programming and testing of machines. You will also be responsible for overseeing the testing and management of electronic process control and regulation equipment. In the industry, you may hear of PLC, or ‘Programmable Logic Controller’, which is essentially a computer that communicates with circuits in an electrical system. Good PLC programming can automate many industrial processes, such as water purification and temperature control.

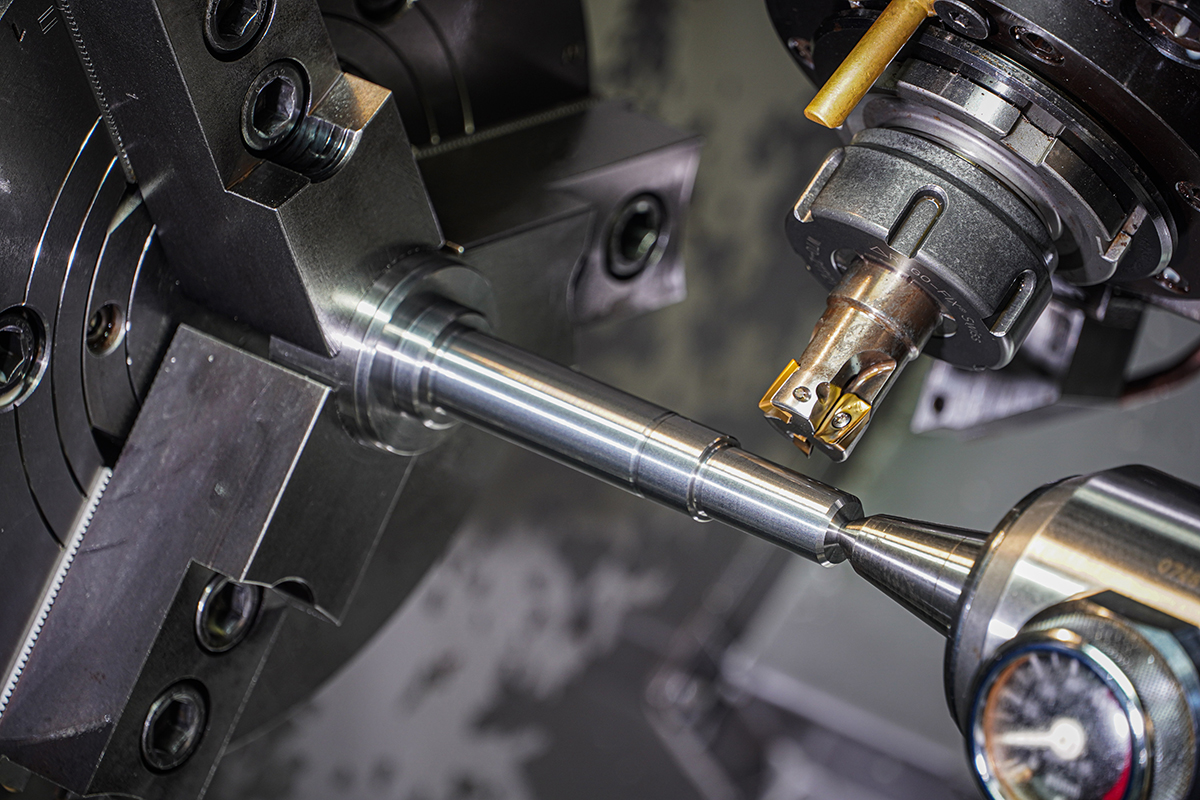

CNC TECHNICIAN

The CNC Technician is responsible for operating numerically controlled machines used for the automated production of mechanical parts. These machines are programmed from the technological and geometric information provided by the CNC Technician himself, who evaluates the shape of the part to be produced from the drawing or machining cycle. The CNC Technician must be familiar with the structure and operation of the machines, the technologies used for production, and the procedures necessary to programme and modify work cycles. These professionals may work in factories, machine shops or any other company that uses CNC machines.

AUTOMATIC SYSTEMS DESIGNER AND DRAUGHTSMAN

The Automatic Systems Designer creates industrial products using advanced computer technology, such as the Cad system to design and visualise the product and the Cam system to programme and manage the operations of the robotic machines that produce the product. This professional works in mechanical engineering companies or professional firms that collaborate with companies in product design, and constantly coordinates with the production department and the sales department to ensure that the product meets the customer’s requirements without violating standard working procedures. The Design Engineer designs in a three-dimensional environment and uses the Cad and Cam system to develop the product, intervening to make changes until the technical specifications necessary for production are obtained.

PRODUCTION MANAGER

The Production Manager is in charge of managing a budget assigned by the company. This budget must be used to purchase raw materials, cover production costs, staff salaries and any maintenance work on machinery in order to achieve the company’s objectives. For this, the Production Manager must carefully evaluate all production-related parameters, known as KPIs or performance indicators, which help determine the results that are analysed with management. Other important factors to be considered are the quantity of products, the quality of raw materials and delivery times, in order to prevent any downturn in company profits. In addition, the Production Manager is responsible for assessing whether there is a need to hire new personnel, monitoring the work of each individual operator and that of the department as a whole, making sure that everyone knows the safety regulations and that they use the relevant protective systems. Finally, he plans any overtime and establishes bonus programmes and production bonuses based on staff performance.

QUALITY CONTROL MANAGER

The Quality Control Manager first establishes the basic characteristics that the product offered must possess in order to be marketed. Based on these criteria, he adopts a quality management system to ensure that the final product meets the desired technical specifications. The activities of the quality manager cover the entire production process. For example, in a company, to ensure that the product that leaves the factory is of excellent quality, the Quality Manager firstly supervises the analysis of the raw materials that enter the production chain. In collaboration with the Buyers and Purchasing Managers, he defines the requirements and technical reference values for the materials and semi-finished products used and periodically checks contracts with suppliers to ensure that these requirements are met. The Quality Manager draws up the necessary procedures to control the production flow and ensure that quality standards are met at all stages of processing, right up to the production of the finished product.

In addition, the Quality Control Manager is the point of contact for customers and companies who want to know the technical details of the product, to ensure maximum customer satisfaction and compliance with market regulations. In this role, he is also in charge of checking the quality of products received from suppliers, to ensure that the suppliers’ quality criteria are correctly applied.

In the event of any product quality problems, the Quality Control Manager coordinates the investigation to identify the cause of the problem and define the corrective actions necessary to prevent its recurrence in the future. In addition, he or she constantly monitors quality control performance data to identify any opportunities for improvement and to suggest to management the actions to be taken to achieve optimal results.